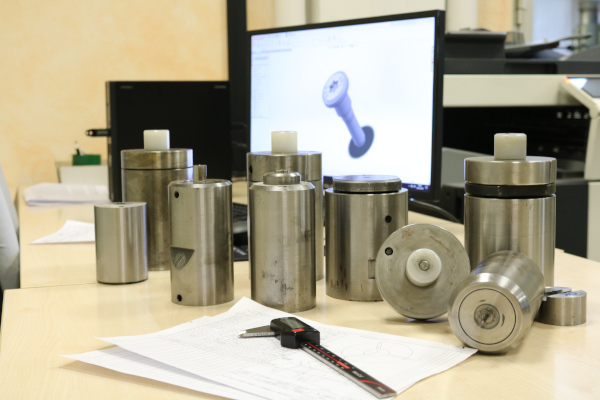

Tooling Internal Design and Manufacturing

Design and manufacturing of production toolings are in-house developed through the support of a 3D CAD software.

This makes the process fast and flexible, meeting any kind of customer’s requirement.

PICKLING AND POLYMER LUBRIFICATION

Bulloneria Usorini is equipped with an innovative, before cold forming, steel wire treatment.

The steel wire, after a traditional sulphuric acid pickling, is lubricated with a polymer based solution.

Substantial advantages in comparison with the old phosphate based solution are:

- Increase of the toolings lifetime

- Reduction of the cooling and lubrication oils pollution with less dirt in the machines.

- Bolts do not need specific de-phosphating washings; this is an appreciated feature for all the components specific for the automotive market.

STAMPING AND THREAD ROLLING

Production with automatic multi-station presses combined with 4 or 5 stations.

Range:

Ø5mm-Ø16mm

L 8mm–145mm

Threading with machines, both roller and comb.

HEAT TREATMENTS, SURFACE TREATMENTS, THREAD LOCKING AND SEALANTS APPLICATION

The heat treatment, surface treatment and sealant applications are entrusted to certified suppliers to ensure the ighest level of quality.

QAUALITY AND CERTIFICATION

Bulloneria Usorini is a IATF 16949 and ISO 9001 certified company.

The whole production process is constantly kept under control by a modern machines monitoring system as well

as by an advanced quality control process in order to established a continuous improvement and guarantee total customer satisfaction.

PACKING AND SHIPPING

The packing takes place inside our warehouse, our staff works closely with the customer

to offer different packaging solutions.

The material is then distributed through affiliated and specialized couriers.